These devices are designed to remain in the tensed or closed position. To compare to mechanical coil springs, the relaxed state of these springs would be when the many coils are close together with no gaps between them. Read More…

Isotech offers a complete line of gas springs for most applications. From steel to stainless steel AISI 303/304 and AISI 316/316Ti, Isotech has the right product for the job. Gas Springs include tension springs, locking gas springs, realease systems, oil dampers, double-stroke springs, and gas spring accessories. Contact us today for more information!

When it comes to manufacturing and supplying gas springs and dampers, we are a global leader. Our choice of gas springs includes integrated gas springs. The automotive and commercial industries use our original equipment to guarantee that their expectations will be met efficiently.

At SUSPA Incorporated, we specialize in crafting top-tier gas spring products designed to meet a wide array of industrial needs. With years of expertise and dedication to innovation, we pride ourselves on delivering superior quality and performance in every gas spring we manufacture.

More Tension Gas Spring Manufacturers

Most gas springs are classified as compression springs and employ the opposite working principle of the tension spring, meaning they are extended when at rest and compressed when force is applied. When at rest, the tension gas spring is fully compressed. The piston and attached rod are retracted into the main cylinder. The inclination to pull shut allows the use of such springs in many industries such as automotive, construction, aerospace, marine, medical and food processing.

In such industries these gas springs help to close and seal doors, hatches, hinges, landing gear, lids and other devices. Providing shock absorption and serving as dampers in the direction of extension, these devices create a tight seal as well as control movement to keep the rate of compression and depression even throughout the stroke.

Also known as traction or reverse acting gas springs, the controlled and sustained movement of these devices makes them preferable to mechanical coil and leaf springs, which just snap back into place instead of providing a controlled release. Considerations to keep in mind when purchasing a tension gas spring include operating temperature, maximum extension and retraction, maximum force, mounting and size.

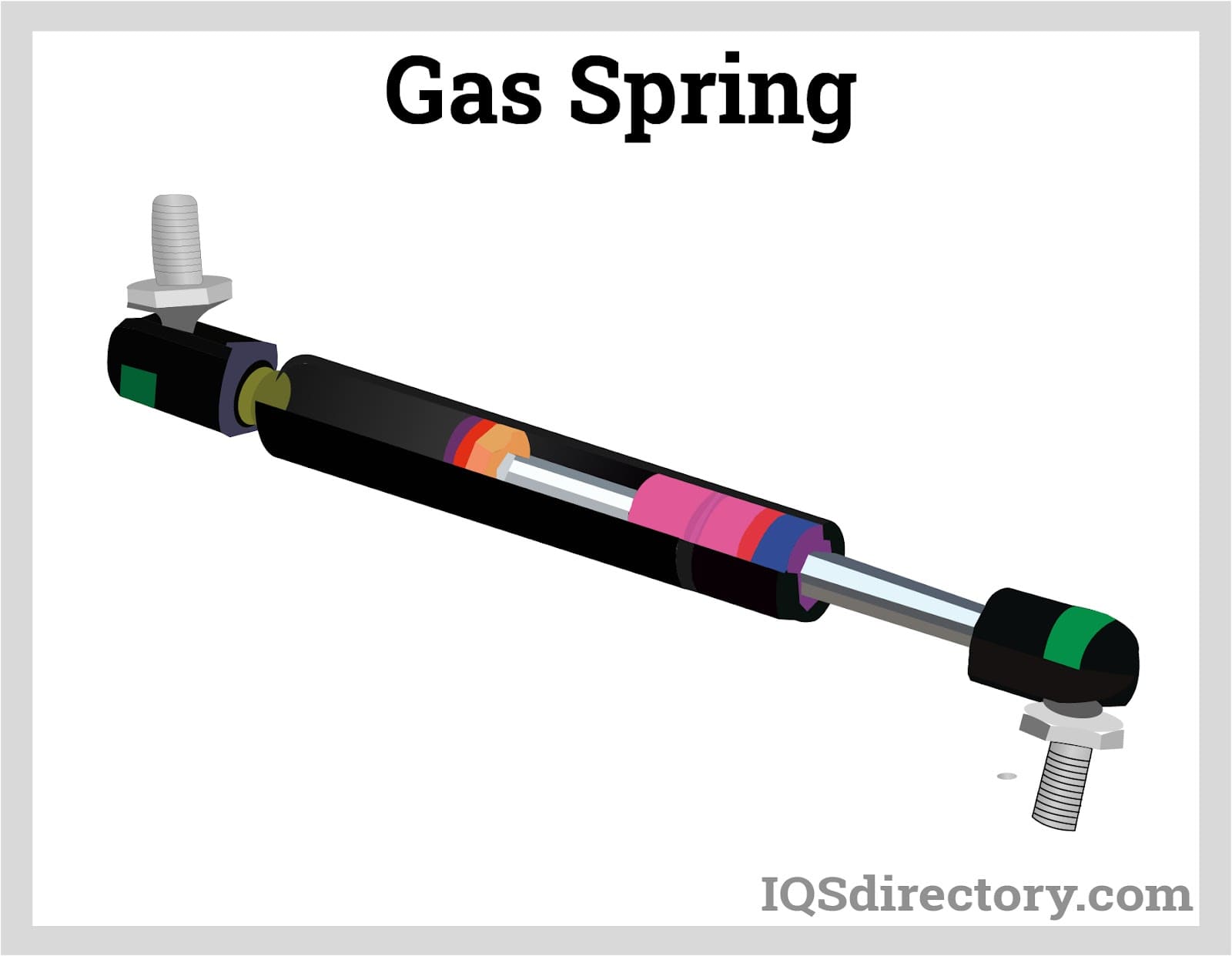

The design is not that disparate from compression gas spring design. The main body of the spring is a sealed cylinder made of durable materials such as steel, stainless steel, aluminum or thermoplastic which is polished to a micro-smooth finish. The interior finish allows the piston head which transects the chamber to slide up and down the barrel without unnecessary friction.

Attached to this head is a rod which is attached at the other end to the external equipment to be supported, protected or sealed. O-rings and seals are used both around the piston head and rod to ensure that the compartments remain air tight. Although the design is similar to most other gas springs, the basic operation of tension springs is very different.

Rather than retract, these springs extend the piston rod when force is applied in the form of compressed air on the opposite side of the piston head, but otherwise pull shut. Locking gas springs that work using tension further ensure an adequate seal for doors, hatches and other enclosures. Locking and adjustable mechanisms are also common to hold these lids and latches open when needed as the natural tendency is for them to pull shut when force is relieved.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services