Also known as shock absorbers, these devices are commonly installed on a variety of vibratory or oscillating industrial equipment such as conveyors and mixers, but are usually associated with vehicle suspension systems and jet or plane landing gears. Read More…

Isotech offers a complete line of gas springs for most applications. From steel to stainless steel AISI 303/304 and AISI 316/316Ti, Isotech has the right product for the job. Gas Springs include tension springs, locking gas springs, realease systems, oil dampers, double-stroke springs, and gas spring accessories. Contact us today for more information!

When it comes to manufacturing and supplying gas springs and dampers, we are a global leader. Our choice of gas springs includes integrated gas springs. The automotive and commercial industries use our original equipment to guarantee that their expectations will be met efficiently.

At SUSPA Incorporated, we specialize in crafting top-tier gas spring products designed to meet a wide array of industrial needs. With years of expertise and dedication to innovation, we pride ourselves on delivering superior quality and performance in every gas spring we manufacture.

More Air Shock Manufacturers

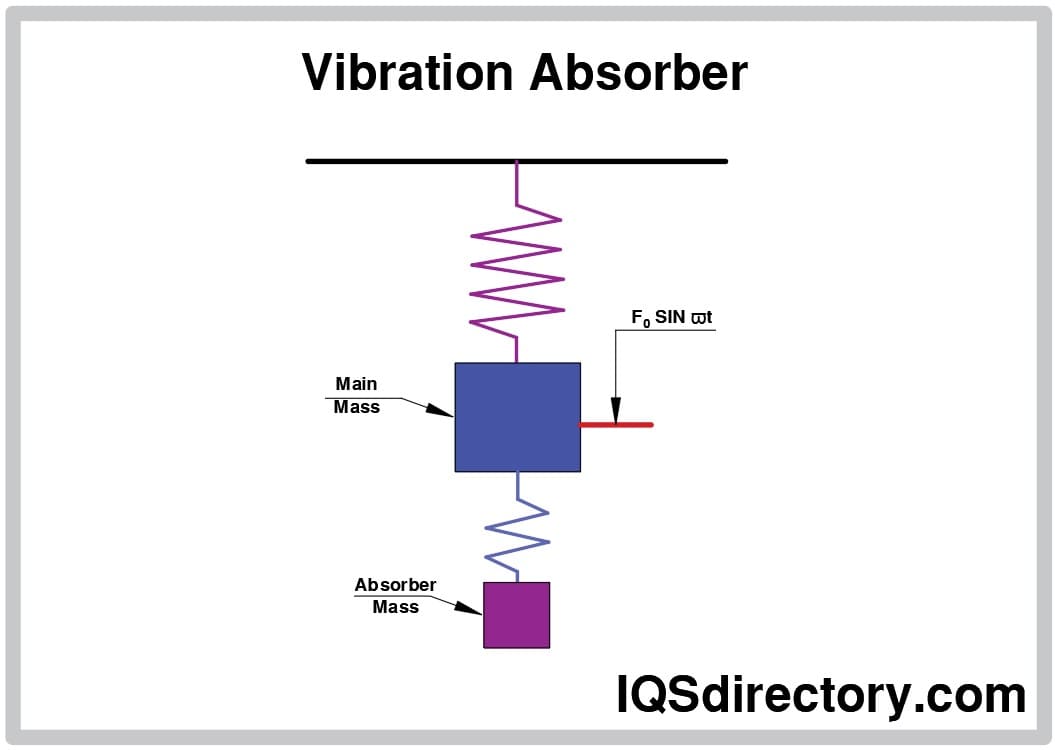

Air shocks utilize a column of air contained within an elastomeric bellows or a metallic cylinder. When a shock or bump is encountered, the force presses on this air supply that then compresses, resisting and absorbing the jolt in order to protect adjacent equipment and provide a smooth operation.

While traditional mechanical springs are available for this purpose as well, air shocks offer improved performance in a compact and clean device. Air springs and shocks also offer better control of movement as the air compresses and decompresses at a near constant rate rather than snapping back into place as is often the case with metal coils.

Additionally, the amount of air in a given shock can be independently adjusted in order to compensate for sharp cornering and imbalanced loading, or simply to raise and lower a vehicle as needed for road conditions and passenger boarding. Air shocks thus provide enhanced performance and accessibility to a number of industries and individuals. Performance specifications include absorber stroke, compressed and extended lengths, type of pressurized gas, maximum force, maximum number of cycles per minute and load capacity.

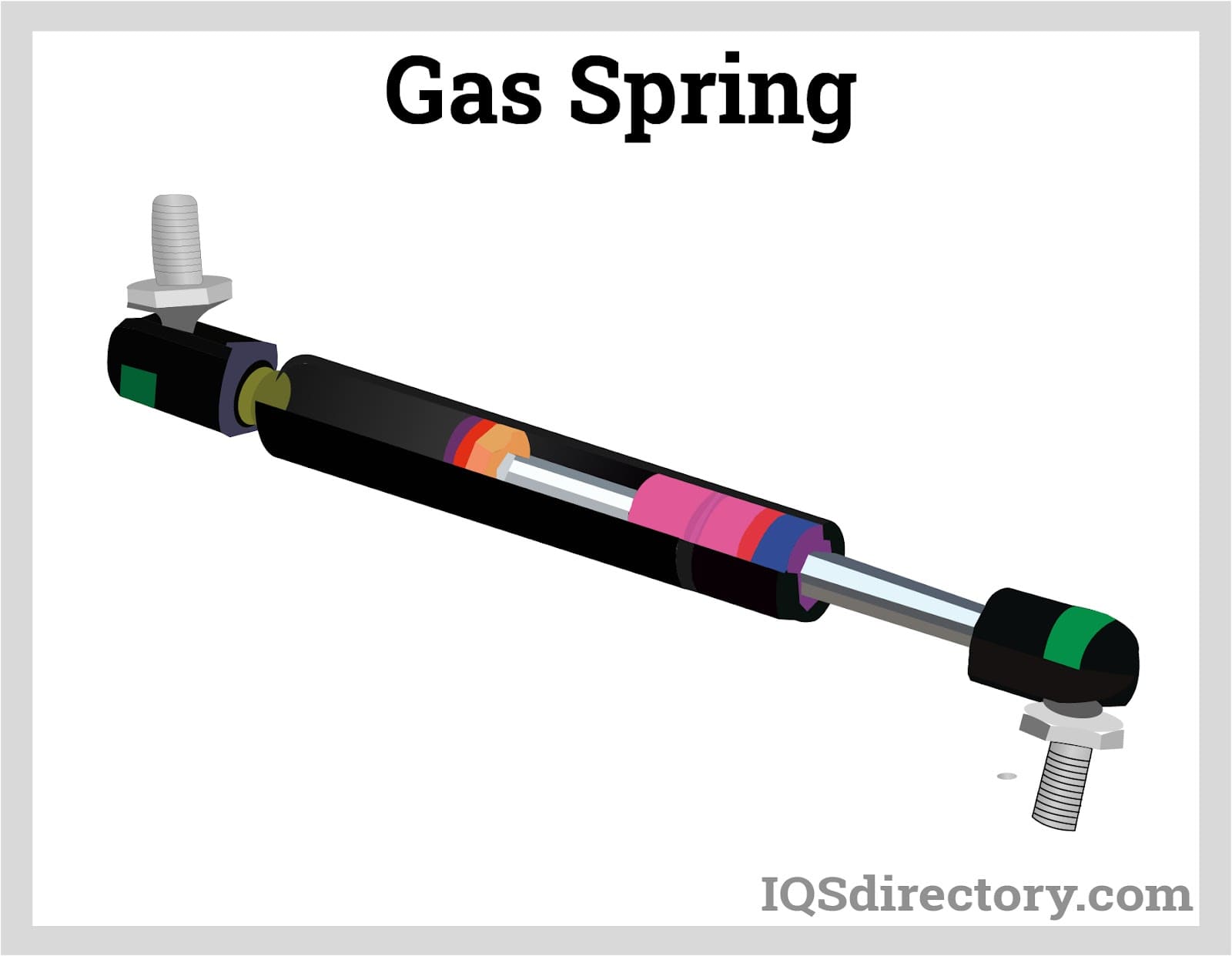

As aforementioned, air shock absorbers are available in two main body types. Cylinder type air shocks utilize the same basic mechanics as all air or hydraulic cylinders. A main body houses a piston head that divides the chamber into two compartments. A rod is attached internally to the piston head and externally to the equipment, the wheel or vehicle frame for example.

This type of shock is most often made of durable materials such as aluminum, steel, stainless steel or thermoplastics. Alternatively, bellows air shocks use an elastomeric or rubber bag that is inflated. As both of these gas spring designs efficiently absorb and dissipate shocks, the body type chosen depends largely on the intended use as both have advantages and disadvantages in specific environments.

Each configuration requires a source of compressed air that is also suited to the environmental conditions that the shock will encounter as this will have a tremendous effect. Temperature, for example, is a key consideration as increases or decreases can significantly alter the pressurization of the shock and therefore impede functionality.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services