Gas springs, sometimes called gas shocks/gas shock absorbers, gas pistons, or gas struts, are springs that pneumatically store energy. They are called gas springs because they receive operating pressure from highly pressurized (compressed) gas. They store this pressure as potential energy, and free it when the piston that seals the energy lifts. Read More…

Isotech offers a complete line of gas springs for most applications. From steel to stainless steel AISI 303/304 and AISI 316/316Ti, Isotech has the right product for the job. Gas Springs include tension springs, locking gas springs, realease systems, oil dampers, double-stroke springs, and gas spring accessories. Contact us today for more information!

When it comes to manufacturing and supplying gas springs and dampers, we are a global leader. Our choice of gas springs includes integrated gas springs. The automotive and commercial industries use our original equipment to guarantee that their expectations will be met efficiently.

At SUSPA Incorporated, we specialize in crafting top-tier gas spring products designed to meet a wide array of industrial needs. With years of expertise and dedication to innovation, we pride ourselves on delivering superior quality and performance in every gas spring we manufacture.

More Gas Spring Manufacturers

In contrast, regular mechanical springs work using elastic deformation. Unlike coil springs that resist impacts due to their structure, gas springs resist shocks because they are powered with pneumatic energy in the form of a high-pressure gas in a cylinder.

Gas springs are similar to air cylinders, in that they both use a piston that compresses or extends based on the pressure in the chamber.

The main functions of gas springs are related to shock absorption, dampening, and exerting force. Gas springs can be used in place of mechanical springs to lift, lower, close, open, and adjust things in a variety of applications.

Industries like aerospace, healthcare, office furniture, marine, and agriculture all use gas springs in their products or in manufacturing equipment. Gas springs are also extremely important in the automobile industry where they are used for everything from suspension to truck supports to hoods. In other industries, gas springs are used for products like landing gear on planes, tanning beds, and awning extensions.

History

The first gas springs were patented in 1891 by Paul Giffard, a Parisian engineer. Giffard designed them for use in guns. In his design, the pressure they built strengthened the force with which a handgun discharged bullets. Independently, gas springs appeared in the United States by at least 1875. Initially, gas springs did not receive much interest.

Gas springs became much more popular in the mid-1900s, when automotive engineers began customizing them for use in the hoods and trunks of cars. After that, manufacturers around the world started using gas springs for other applications.

Design

To construct gas springs, most manufacturers make use of 3D CAD drawings or similar design software for maximum precision.

Materials

Body Materials

Manufacturers most often create gas springs using metals like stainless steel and aluminum. Stainless steel gas springs are extremely common, as they can resist corrosion. Manufacturers can also, however, fabricate them using other materials, like EPDM synthetic rubber or polyurethane.

If the application calls for it, manufacturers can coat the spring material with chrome plating or black nitride; such coatings will further protect the spring from the elements.

Gas Material

Usually, manufacturers choose nitrogen or carbon as the gas that passes through the gas spring. Nitrogen gas springs are popular because nitrogen gas is inert, meaning that it is chemically inactive (it won’t react). Carbon gas springs are popular because carbon gas is generally harmless and compatible with industrial manufacturing.

Considerations and Customization

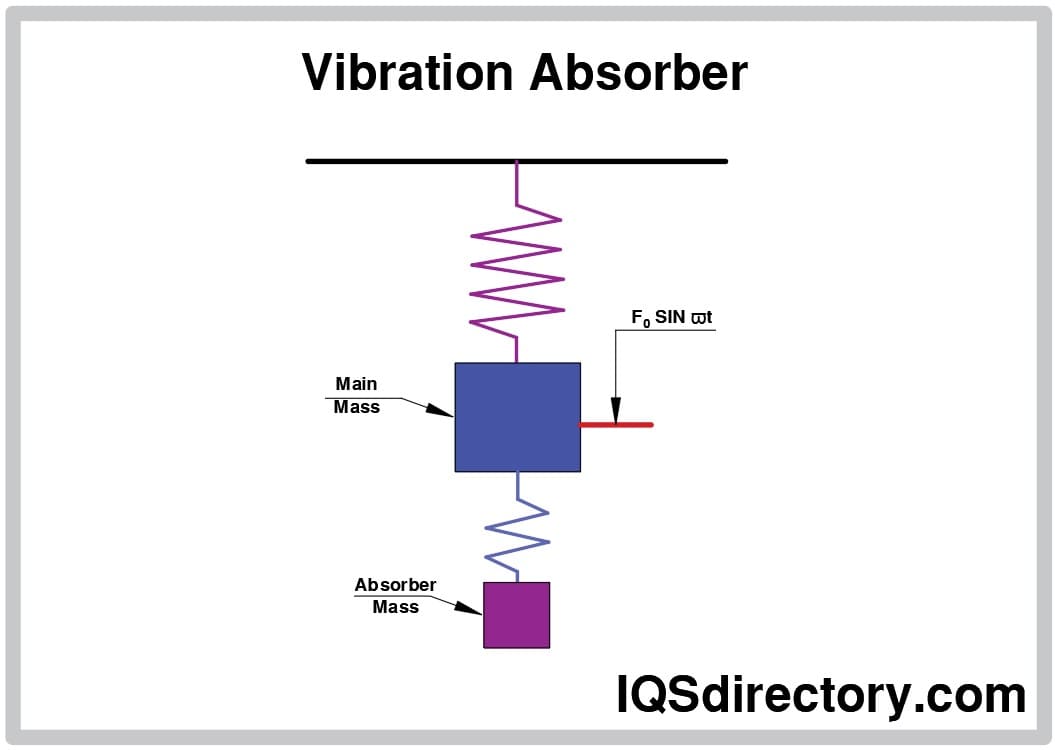

When designing a gas spring, manufacturers must take a number of factors into consideration. These include the amount of gas that is expected to pass through the chamber, the application’s actuation or vibration isolation needs, and the variable pressures and velocities it must tolerate (especially important in machinery and automotive applications).

Based on these considerations and other application requirements, gas spring manufacturers custom design spring features like the size (which depends on the amount of gas that is expected to pass through the chamber), compressed and extended spring lengths, load capacity, max force exertion per minute, maximum cycles per minute, the type of gas they will use in the cylinder, absorber stroke, and working temperatures.

A gas cylinder can be as small as two inches in length, or as large as several feet in length. Likewise, load capacity can range from one-hundred to over eighty thousand pounds. Manufacturers most often customize gas springs in relation to their body material, as the material they use must be able to endure any stresses put on it from the environment it inhabits (heat, cold, moisture, etc.), the chemicals it uses (corrosive chemicals, hazardous chemicals, etc.), and the physical stresses put on it. On top of that, it must be appropriate for the standard requirements of the application. For example, in pharmaceutical manufacturing or in the food industry, the gas springs must be FDA-compliant.

To find out more about your custom gas spring options, talk to your prospective suppliers.

Features

Gas springs all have a similar design and function, but they can be used for many different applications and can be manufactured in a wide range of sizes.

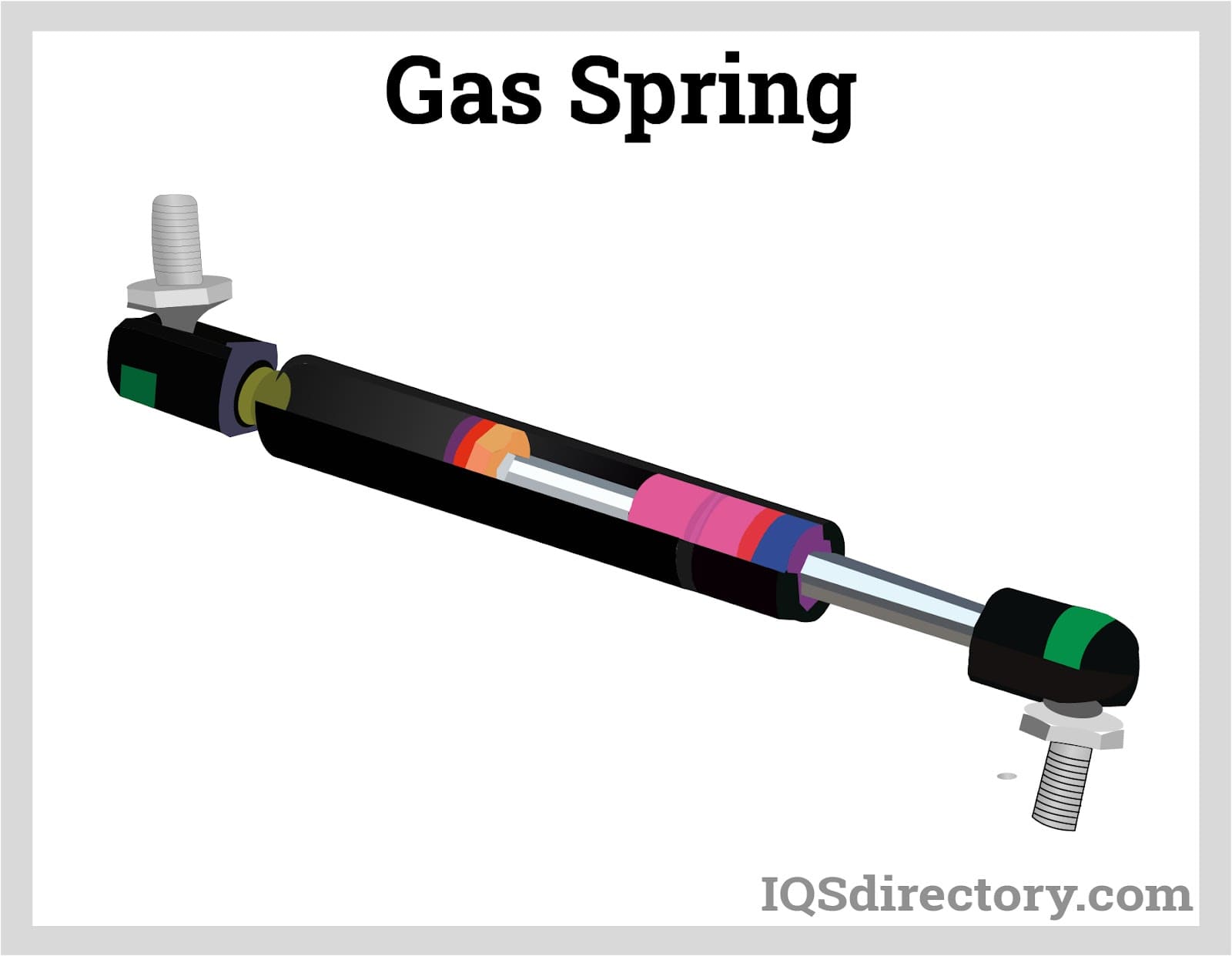

Essentially, all gas springs have a cylinder body, piston rod, O-rings (or other seals), intake and outlet valves, and a gas reservoir.

The polished interior of the cylinder helps to reduce friction during motion. The head piston of the spring sits perpendicular to create an airtight seal and separate the cylinder into two compartments.

The rod extends out of the end of the cylinder and is attached to the piston. When force is placed on the spring, the rod goes deep into the chamber. This is what compresses the gas and reduces the impact. A common example of this is when a car drives over a bump. The force of the impact causes the car’s springs to momentarily compress.

Types

There are several types of gas springs. Some of them include compression gas springs, extension gas springs, tension gas springs, locking gas springs, adjustable gas springs, reducible gas springs, tool and die gas springs, gas spring dampers, gas struts, and lift gas springs.

Compression gas springs offer dampening when force is exerted on the spring as the piston is pushed into the cylinder.

Extension gas springs push the rod all the way out or partially out in the chamber to provide isolation.

Tension gas springs hold tension and/or carry out pulling tasks. In contrast, regular gas springs perform pushing tasks. Tension gas springs are common components of furniture like cabinets.

Locking gas springs are those gas springs that can lock their rod in place after they have reached full extension. Locking gas springs are also known as lockable gas springs. They are useful for applications that require controlled movements and prolonged positioning (e.g. extended hospital bed).

Adjustable gas springs can stop at any point during movement. Regular gas springs can only stop at full extension. Adjustable gas springs, which are typically locking, provide a greater degree of control for their users. Most often, manufacturers install them on hospital furniture, like beds, emergency gurneys, and seats.

Reducible gas springs are adjustable in a different way; during operation, users can remove some of the gas they use in order to alter their force.

Tool and die gas springs do not use any damping agents. At the same time, they produce higher forces using shorter stroke lengths than conventional gas springs.

Gas spring dampers are not really gas springs, but people so often use the term “dampers” in reference to gas springs that we have to mention them. Dampers are basically gas springs that control motion without any gas exertion. Their main application is supporting moving loads and controlling their motion.

Gas struts usually offer push forces.

Lift gas springs are those gas springs used specifically for lifting applications.

Advantages

Gas springs compete against other types of mechanical springs, such as coil springs and leaf springs, as well as hydraulic and pneumatic systems. Each of these alternatives serves to store and release mechanical energy, but they differ in their mechanisms and applications.

Compared to traditional coil springs, gas springs offer several advantages. First and foremost, gas springs provide a smoother and more controlled motion. They feature a dampening effect that prevents sudden jolts or rebounds, making them ideal for applications requiring precise and controlled movement, such as automotive suspension systems and office chairs. Additionally, gas springs are more compact and lightweight, making them easier to integrate into various designs and reducing the overall weight of the system. This characteristic is especially valuable in automotive engineering, where weight reduction is crucial for fuel efficiency and performance.

When competing against leaf springs, gas springs demonstrate superior versatility and adjustability. Leaf springs are often limited in terms of adjustability, making them less suitable for applications where specific force or motion requirements need to be met precisely. On the other hand, gas springs can be customized to provide a wide range of forces and lengths, allowing engineers to tailor their performance to specific needs. This adaptability makes gas springs preferred in industries like furniture, aerospace, and industrial machinery, where fine-tuning and precision are essential.

Regarding hydraulic and pneumatic systems, gas springs offer distinct advantages in simplicity and reliability. Hydraulic systems rely on fluid-filled chambers and pumps, which can be complex and prone to leakage, requiring frequent maintenance. Pneumatic systems, while simpler than hydraulics, are still more intricate than gas springs. In contrast, gas springs have a straightforward design with fewer moving parts, reducing the likelihood of mechanical failure and minimizing maintenance requirements. Moreover, gas springs don’t require a continuous power source like hydraulic or pneumatic systems, making them more energy-efficient and cost-effective in various applications.

In conclusion, gas springs have clear functional advantages over their competitors. Their smooth and controlled motion, compact size, versatility, and simplicity make them an excellent choice in diverse industries, from automotive and furniture to aerospace and machinery. Their ability to provide precise force and motion control while being reliable and easy to maintain gives them a competitive edge over traditional coil springs, leaf springs, hydraulic systems, and pneumatic systems.

Accessories

Accessories for gas springs play a crucial role in enhancing the functionality and versatility of these mechanical components. Some common accessories include nylon socket end fittings, stainless steel socket end fittings, O-ring seals, mounts/mounting brackets, ball receivers, and various connectors.

Nylon Socket End Fittings

Nylon socket end fittings are designed to provide a secure and flexible connection between the gas spring and its mounting point. The nylon material offers excellent durability and resistance to wear, ensuring a long service life. These fittings are often used in applications where a smooth and silent operation is required, such as office chairs and medical equipment.

Stainless Steel Socket End Fittings

Stainless steel socket end fittings are chosen for their superior strength and corrosion resistance. They are well-suited for outdoor and marine applications, as well as environments where exposure to harsh conditions or chemicals is a concern. Industries like aerospace and heavy machinery commonly use these fittings for their durability and reliability.

O-Ring Seals

O-ring seals are used to prevent gas leakage from the gas spring cylinder, ensuring a tight seal. They are essential to maintain consistent pressure and prevent contamination, ensuring the gas spring operates efficiently and safely. O-ring seals are vital in applications like automotive suspensions and industrial machinery.

Mounts/Mounting Brackets

Mounts or mounting brackets provide the means to attach the gas spring to the intended structure or object. These accessories offer different mounting orientations, allowing gas springs to be positioned vertically, horizontally, or at various angles. Properly chosen mounts ensure the gas spring’s efficient operation and alignment with the application’s requirements.

Ball Receivers

Ball receivers are components that create a ball-and-socket joint, providing flexibility and a wide range of motion to the gas spring. They allow gas springs to pivot and rotate freely, making them ideal for applications that require multidirectional movement, such as automotive hoods and trunk lids.

Connectors of Various Kinds

Connectors enable the gas spring to be attached to other elements or components of a system. They come in various designs, including eyelet connectors, clevis connectors, and threaded connectors. The choice of connector depends on the specific application and the type of attachment required.

Knowing if you need any of these accessories depends on your application’s requirements. If you are designing or modifying a system that involves gas springs, you should consider factors like load capacity, range of motion, environmental conditions, and the desired degree of flexibility and precision in movement. If your application involves special mounting orientations, heavy-duty usage, or exposure to corrosive elements, then accessories like stainless steel socket end fittings and ball receivers might be essential.

To acquire these accessories, you can reach out to specialized gas spring manufacturers, distributors, or suppliers. Many companies offer a wide range of gas spring accessories, and they can provide expert guidance on selecting the right accessories based on your specific needs and application requirements. These accessories are often available for purchase individually or as part of a gas spring assembly kit, making it convenient to source them for your project. Additionally, online marketplaces and industrial supply stores may also offer a variety of gas spring accessories for purchase.

Proper Care

To make sure that your gas springs last as long as possible, you need to treat them well. What entails treating them well?

Well, first, you need to use them only within their designed limits. This means that you should not exceed their load capacities; you should not put them in temperatures they are not meant to endure; you should not put them in overly corrosive environments, etc. Putting them in settings for which they are not involved will wear them out quickly, and quite possibly cause a malfunction that will break them completely. It’s also not safe.

Second, to keep your gas springs working well, you need to check on them from time to time. They actually do not require regular maintenance, but you want to be aware if something has gone wrong, which is why you should check on them.

If the time does come for you to replace your gas spring, first depressurize them, then drain them. After that, if you can, recycle them.

Standards

In the United States, the standards regarding the creation and use of gas springs are established and regulated by several agencies and organizations. The American National Standards Institute (ANSI) is a prominent organization involved in setting standards for various industries, including gas springs. ANSI provides guidelines and specifications for the design, manufacturing, testing, and safety requirements of gas springs. Another organization, the International Organization for Standardization (ISO), develops international standards that are often adopted or referenced by U.S. regulatory bodies and industry associations.

Using gas springs that do not meet these established standards can have serious consequences. Such non-compliant gas springs may pose safety risks, as they might not withstand intended loads or may fail prematurely, leading to accidents or injuries. Additionally, using non-standard gas springs could result in subpar performance, increased maintenance costs, and potential legal liabilities. Compliance with recognized standards ensures that gas springs meet stringent quality and safety criteria, promoting reliability, longevity, and consistent performance.

The benefits of using gas springs that meet established standards are manifold. To start, adhering to standards ensures that the gas springs have undergone rigorous testing and evaluation, guaranteeing their performance under specified conditions. This compliance leads to increased trust in the product’s reliability, making it a preferred choice for engineers and designers in various industries. Secondly, meeting standards enhances compatibility and interchangeability, allowing gas springs to be seamlessly integrated into existing systems and applications. Additionally, compliant gas springs are more likely to have clear documentation and user guidelines, facilitating proper installation and maintenance procedures. Ultimately, using gas springs that meet recognized standards contributes to improved safety, greater efficiency, and higher customer satisfaction. It also ensures that manufacturers, suppliers, and end-users are in compliance with relevant regulations and industry best practices, fostering a responsible and accountable approach in the gas spring industry.

Things to Consider

To help guide you, we have put together a list of several high-quality gas spring manufacturers that we trust. You can find these gas spring suppliers by scrolling towards the middle of this page. There, you will find their contact info, webpage links, and profiles.

Before you check out these manufacturers, we recommend that you dedicate some time to putting together a specifications list. List all of the details of your application, including things like your budget, your timeline, your delivery preferences, and your post-delivery support preferences (parts replacement, warranties), etc. Once you have put this list together, you can use it to help you determine which of the suppliers we have recommended are most likely to work for you. Based on your specifications, pick three or four potential choices. Then, reach out to each of them to go over your application. When you speak with each of them, use your specifications list as a conversation guide and make sure to go over every point. After you have spoken with each potential manufacturer, compare and contrast the services each company offers. Also compare and contrast their prices. Weigh your options and, finally, pick the right company for you.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services