Gas lifts are an artificial lift technique that involves injecting external gas into the produced flow path at a certain depth in the wellbore. The extra gas boosts the formation gas and lowers the bottom-hole pressure while flowing, which boosts the production of fluids. The amount of injected gas is calculated for dewatering gas wells so that, particularly for lower liquid-producing gas wells, the combined deposit and injected gas will be over the critical rate for the wellbore. The design process may resemble developing oil well gas lift procedures for higher liquid rates. Read More…

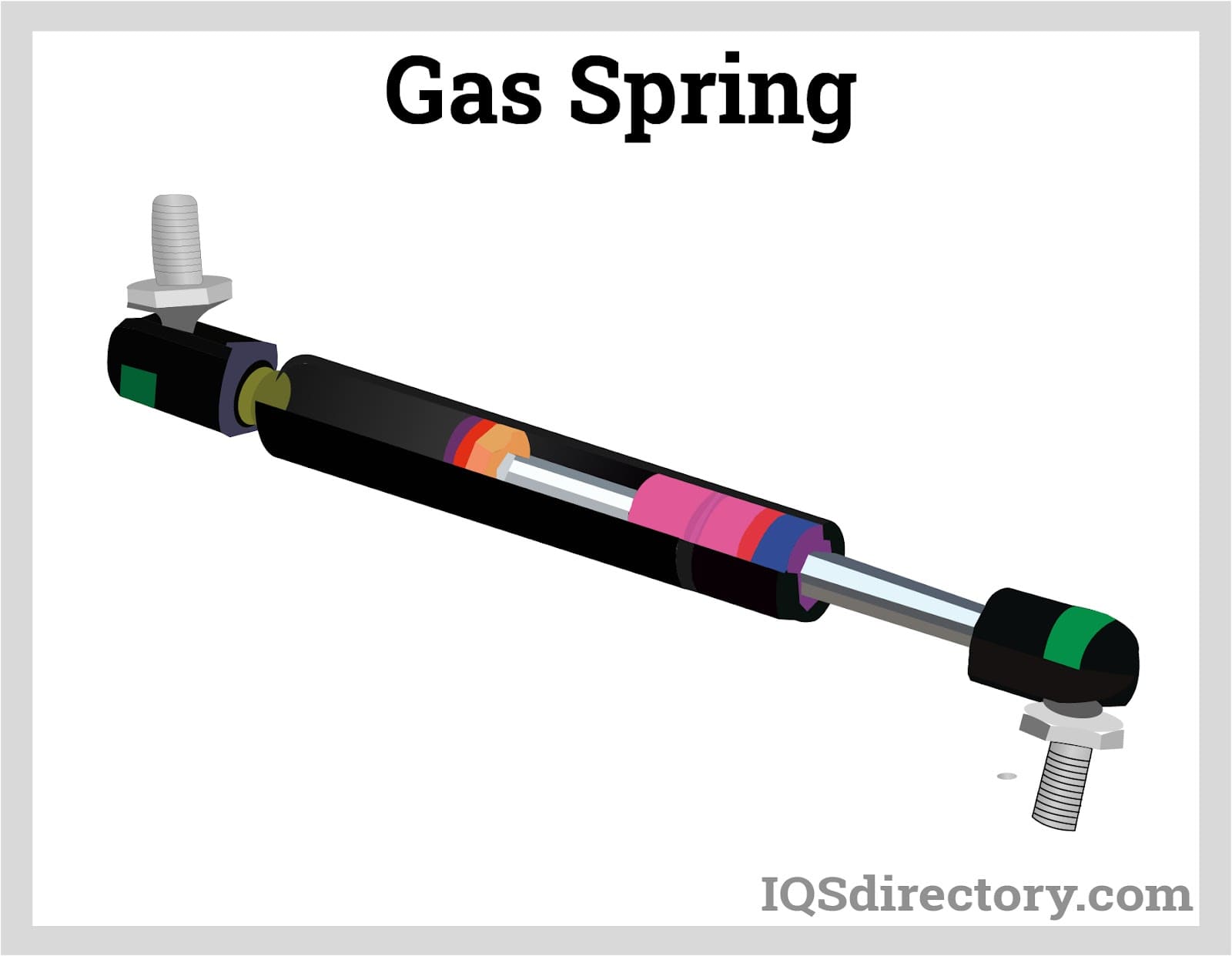

Isotech offers a complete line of gas springs for most applications. From steel to stainless steel AISI 303/304 and AISI 316/316Ti, Isotech has the right product for the job. Gas Springs include tension springs, locking gas springs, realease systems, oil dampers, double-stroke springs, and gas spring accessories. Contact us today for more information!

More Gas Lift Manufacturers

Comprehensive Guide to Gas Lift Systems: Types, Applications, and How to Choose the Right Manufacturer

Gas lift systems are a critical form of artificial lift technology widely used in the oil and gas industry to enhance or restart well productivity when reservoir pressure is insufficient to lift fluids naturally to the surface. While a gas lift system may not reduce the flowing pressure more than a highly optimized pumping system, it offers numerous advantages that make it a preferred artificial lift method for many well types and production scenarios. Especially in oil wells and gas wells producing limited quantities of liquids, gas lift can be more efficient and cost-effective than alternatives like electric submersible pumps (ESPs), rod pumps, or jet pumps.

Gas lift technology works by injecting high-pressure gas into the wellbore, which reduces fluid density and bottom-hole pressure (BHP), facilitating the upward movement of oil, water, or condensate to the surface. For both mature and unconventional fields, gas lift plays a pivotal role in maximizing hydrocarbon recovery, managing liquid loading, and extending well life cycles.

Types of Gas Lifts Used in Oil and Gas Production

The oilfield industry primarily utilizes two basic forms of gas lift systems, each suited to specific well characteristics and production needs:

- Continuous Gas Lift

- Intermittent Gas Lift

Continuous Gas Lift

A continuous gas lift system involves the constant injection of pressurized gas into the production tubing through a downhole gas lift valve or orifice. This injected gas stream mixes with the produced fluids, lowering the hydrostatic head of the fluid column and enabling easier flow to the surface. The main mechanisms at play in continuous gas lift systems include:

- Reducing the overall column weight and fluid density, which increases the pressure differential between the wellbore and the reservoir.

- Expanding injected gas to push liquid ahead, thereby decreasing the column weight and promoting upward flow.

- Displacing liquid slugs with large gas bubbles acting as pistons.

While continuous-flow gas lift systems can maintain steady production rates, they often create relatively high backpressure in the reservoir compared to mechanical pumping methods. Power efficiency can be lower, resulting in higher operating costs due to energy consumption and the need for gas compression infrastructure. Nevertheless, continuous gas lift remains a staple in artificial lift for many well configurations, particularly where sand production, deviated wellbores, or high gas-to-liquid ratios are present. Advanced numerical modeling and gas lift optimization software help engineers design and manage these systems efficiently.

Advantages of Continuous Gas Lift

- Excellent for wells producing sand or other solids. Unlike most mechanical pumps, gas lift systems are less prone to damage from abrasive materials, making them ideal for wells with sand production, even with sand control measures in place.

- Highly adaptable to a wide range of well conditions, including deviated or crooked holes. This flexibility is especially valuable in offshore and directional drilling scenarios.

- Subsurface equipment is relatively inexpensive and typically requires less frequent maintenance and repair compared to other artificial lift techniques.

- Continuous gas lift is well-suited for offshore platforms and fields where gas supply is readily available and infrastructure for gas compression is already in place.

- Allows for remote and automated control, supporting smart well operations and digital oilfield initiatives.

Disadvantages of Continuous Gas Lift

- Reduced efficiency when lifting heavy or low-gravity crude oils due to higher friction losses, liquid fallback, and gas fingering.

- Requires a reliable and continuous supply of injection gas for sustained operations, which can be a limiting factor in remote locations or in fields with gas scarcity.

- Can generate significant backpressure, potentially limiting productivity in low-pressure reservoirs.

- Initial capital expenses for gas compressors and surface facilities can be high, and ongoing energy costs may reduce overall economic efficiency compared to other artificial lift methods.

Intermittent Gas Lift

Intermittent gas lift is designed for wells that produce lower volumes of liquid. This method periodically injects slugs of high-pressure gas into the production tubing, propelling accumulated liquid slugs to the surface in bursts. The process is analogous to firing a bullet from a gun—the gas “charges” behind the liquid, quickly expanding when the gas lift valve opens, and delivers the fluid to surface facilities.

Intermittent gas lift systems are generally used for wells with fluid production rates between 150 and 200 barrels per day (B/D), though some advanced systems can handle up to 500 B/D. They are especially effective in mature fields, marginal wells, and gas wells afflicted by liquid loading, where traditional continuous gas lift may not be viable due to low reservoir pressure or limited gas supply.

Advantages of Intermittent Gas Lift

- Operates at much lower bottom-hole pressures than continuous gas lift, making it suitable for depleted or marginal wells.

- Efficiently handles small amounts of produced fluids, helping to extend the productive life of aging or low-productivity wells.

- Lower surface equipment investment and operational complexity compared to some mechanical lift systems.

- Can be a cost-effective solution for wells experiencing liquid loading without the need for significant infrastructure upgrades.

Disadvantages of Intermittent Gas Lift

- Best suited only for low-volume wells; not practical for high-rate production scenarios.

- Generally less energy efficient than continuous gas lift—more gas is typically consumed per barrel of produced fluid.

- Requires frequent adjustments and monitoring to maintain efficient lift performance.

- Production rates are inherently lower and less stable compared to continuous systems, potentially impacting field economics.

Key Applications and Use Cases for Gas Lift Systems

Gas lift is a versatile artificial lift method with broad applications in the upstream oil and gas sector, including:

- Oil and Gas Well Production Optimization: Gas lift is extensively used to enhance production in wells with declining reservoir pressure or high gas-to-oil ratios. It is particularly effective for maximizing recovery from mature fields and extending the economic life of producing assets.

- Liquid Loading Management in Gas Wells: In gas wells suffering from liquid loading that impedes gas flow, gas lift helps remove accumulated fluids, restoring well deliverability and preventing production shutdowns.

- Offshore and Subsea Well Operations: Due to its flexibility and reliability, gas lift is a preferred solution for artificial lift on offshore platforms and subsea wells, where space, weight, and maintenance access are limited.

- Sand and Solids Handling: Gas lift systems are ideal in wells where sand, scale, or other solids are produced, as they are less susceptible to damage compared to mechanical pumps.

- Unconventional Resources: In shale plays and tight formations, gas lift is often deployed as a primary or secondary artificial lift method due to its adaptability and ease of reconfiguration as reservoir conditions change.

- Startup and Unloading of New Wells: Gas lift can be used temporarily to unload completion fluids and kick-start production before transitioning to other artificial lift technologies if required.

Limitations and Challenges of Gas Lift Technology

Despite its many benefits, gas lift systems have certain limitations and operational challenges that must be considered during the artificial lift selection process:

- Gas Supply Constraints: The primary limitation is the availability of injection gas. If neither a suitable formation gas nor imported gas is available, implementing a gas lift system becomes impractical.

- Compressor Requirements: Gas compressors are capital-intensive and require regular maintenance, especially in offshore or space-constrained environments. Compressor downtime increases operating costs and can interrupt production.

- Well Spacing and Field Layout: Widely spaced wells or single-well installations may not justify the investment in gas lift infrastructure, making other artificial lift methods more suitable.

- Hydrate and Corrosion Risks: In wet gas environments without adequate dehydration, hydrate formation and corrosion can impair gas lift performance and system reliability.

- Backpressure Effects: High backpressure from continuous gas lift can reduce well inflow, particularly in low-pressure reservoirs, affecting ultimate recovery and economic returns.

Are you comparing artificial lift methods for your well or field? Read on to learn how to evaluate the best gas lift solution and select a reputable gas lift equipment manufacturer.

Decision Factors: How to Choose the Right Gas Lift System and Manufacturer

Selecting the optimal gas lift system—and the right manufacturer—is crucial for project success, cost efficiency, and long-term well performance. Consider the following factors when researching and evaluating gas lift equipment and suppliers:

- Well Characteristics: Assess your well's production rate, fluid composition (oil, water, gas, sand), reservoir pressure, and geometry (vertical, deviated, or horizontal). These factors influence the selection between continuous and intermittent gas lift, as well as valve and tubing design.

- Production Goals: Define your production targets, expected well life, and operating conditions to ensure the gas lift system can accommodate changing reservoir dynamics.

- Gas Availability: Ensure a reliable source of injection gas and evaluate the economics of gas compression, processing, and delivery for your specific field location.

- Surface and Subsurface Equipment: Consider the compatibility of gas lift valves, mandrels, surface controls, and automation systems with your overall field infrastructure. Look for manufacturers offering integrated solutions and support for digital oilfield initiatives.

- Operational Support: Choose vendors with proven field experience, robust technical support, and responsive service for troubleshooting, maintenance, and system upgrades.

- Cost and ROI: Evaluate not just initial capital costs but also long-term operational expenses, downtime risks, and expected incremental recovery to maximize return on investment (ROI).

- Environmental and Regulatory Compliance: Ensure your gas lift installation meets local, regional, and international standards for safety, emissions, and operational integrity.

How to Evaluate Gas Lift Manufacturers and Suppliers

To achieve the best outcome when purchasing gas lift systems, components, or services, it is essential to compare several gas lift manufacturers and suppliers. Use the following approach to streamline your selection process:

- Browse our comprehensive directory of gas lift manufacturers to discover suppliers with expertise in your specific application—onshore, offshore, shale, or conventional fields.

- Visit each manufacturer's business profile page to review their product range, technical capabilities, certifications, and areas of specialization. Many profiles include a contact form to request additional information or a customized quote.

- Utilize our proprietary website previewer to quickly assess each company’s focus—whether they excel in gas lift valves, mandrels, compressor packages, system integration, or turnkey artificial lift solutions.

- Leverage our simple RFQ (Request for Quote) form to contact multiple gas lift companies simultaneously. This saves time and ensures you receive competitive proposals and technical input tailored to your project requirements.

- Request case studies, client references, and details of project experience in similar operating environments to validate your selection.

- Consider after-sales support, warranty coverage, and availability of local field service technicians.

Frequently Asked Questions About Gas Lift Systems

- What are the main differences between gas lift and other artificial lift methods? Gas lift uses pressurized gas to reduce fluid density and lift liquids to the surface, while other methods like ESPs, rod pumps, or hydraulic pumps use mechanical energy to move fluids. Gas lift is more tolerant of solids and deviated wells, but requires access to injection gas and compressor infrastructure.

- When should I choose continuous vs. intermittent gas lift? Continuous gas lift is preferred for higher-volume wells with steady production rates and available gas supply, while intermittent gas lift is ideal for low-rate, marginal, or liquid-loaded wells with limited gas or reservoir pressure.

- How do I optimize my gas lift system? Work with experienced engineers and use advanced modeling tools to design lift gas injection rates, valve spacing, and mandrel placements. Regularly monitor system performance and adjust as reservoir conditions change.

- What maintenance is required for gas lift equipment? Routine inspection and servicing of compressors, valves, and control systems are essential to minimize downtime and maintain reliable operation. Sand, scale, or corrosion may require additional preventive measures.

- Can gas lift be used in horizontal or unconventional wells? Yes, gas lift is highly adaptable and often used in horizontal, deviated, and shale wells due to its ability to manage complex well trajectories and variable production conditions.

- What is the typical lifespan of a gas lift system? With proper maintenance and periodic upgrades, gas lift systems can operate reliably for many years, making them a cost-effective artificial lift strategy over the life of a well or field.

Ready to Source Gas Lift Systems or Services?

If you are ready to find the best gas lift system or need guidance on selecting the right artificial lift technology for your project, start by exploring our gas lift manufacturer directory. Use our RFQ feature to connect directly with expert suppliers and compare solutions tailored to your specific well, field, or operational needs.

Want to learn more about the benefits of gas lift, system design, or troubleshooting? Contact our technical team for personalized advice. Stay ahead in the evolving landscape of oilfield production with advanced, efficient gas lift solutions.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services